Business, 12.02.2020 04:18 jones03riley

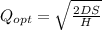

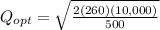

A steel rolling mill can produce I-beams at the rate of 20 tons per week. Customer demand for the beams is 5 tons per week. To produce I-beams, the mill must go through a setup that requires changing to the appropriate rolling patterns. Each setup costs the mill $10,000 in labor and lost production. I-beams cost the mill $2,000 per ton and the mill has an annual holding cost of 25 percent. What is the optimal production batch size for I-beams?

Answers: 1

Another question on Business

Business, 22.06.2019 15:20

Kelso electric is debating between a leveraged and an unleveraged capital structure. the all equity capital structure would consist of 40,000 shares of stock. the debt and equity option would consist of 25,000 shares of stock plus $280,000 of debt with an interest rate of 7 percent. what is the break-even level of earnings before interest and taxes between these two options?

Answers: 2

Business, 22.06.2019 19:50

Ichelle is attending college and has a part-time job. once she finishes college, michelle would like to relocate to a metropolitan area. she wants to build her savings so that she will have a "nest egg" to start her off. michelle works out her budget and decides she can afford to set aside $9090 per month for savings. her bank will pay her 4 %4% per year, compounded monthly, on her savings account. what will be michelle's balance in five years?

Answers: 3

Business, 22.06.2019 22:40

When immigration adds to the size of the domestic labor pool, which of the following is likely to occur? a. wages decrease. b. productivity increases. c. consumption decreases. d. minimum wage increases.

Answers: 1

You know the right answer?

A steel rolling mill can produce I-beams at the rate of 20 tons per week. Customer demand for the be...

Questions

Chemistry, 23.07.2019 03:30

Mathematics, 23.07.2019 03:30

Mathematics, 23.07.2019 03:30

Mathematics, 23.07.2019 03:30

History, 23.07.2019 03:30

Biology, 23.07.2019 03:30

Mathematics, 23.07.2019 03:30