Business, 07.03.2020 05:36 StrangerMo

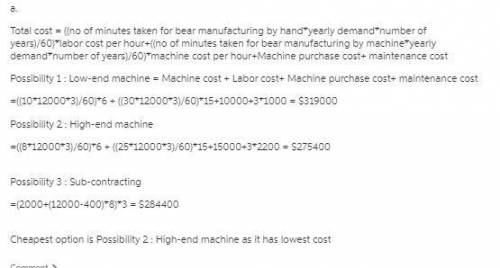

A company producing custom-made teddy bears is considering several options for expanding their existing capacity. There are 3 possibilities. The first is a low-end machine, which would take 10 minutes/bear for the (machined) manufacturing process. In addition, an average of 30 minutes of detail work would have to be done by hand (per bear). The second option is a high-end machine, which would take 8 minutes/bear, and reduce the amount of hand detail work to 25 minutes/bear. The final option is to subcontract out the bears. The subcontractor is willing to provide up to 400 bears per year for a flat fee of $2,000. Additional bears would cost $8 each. There is no difference in bear quality between the 3 options. It costs $10,000 to buy the low-end machine. Yearly maintenance is $1,000. The purchase price for the high-end machine is $15,000, while maintenance is $2,200. Management estimates the cost for running a machine at $6/hour. Labor costs are $15/hour. Assume the factory runs 350 days/year for 8 hours/day. a) If you expect a yearly demand of 12,000 bears, which option is the cheapest over a 3-year time horizon?b) If the service times on both machines are Exponentially distributed, and the job arrivals have a Poisson distribution with a rate as specified in part a), what is the expected time between the job's arrivals at the factory to the time it is complete and can leave? (Assume that there are more than enough workers to cover the hand detail workc) At what arrival rates (demand levels) would the different options make sense, given a 3-year time horizon?Please write down the answer step by step

Answers: 3

Another question on Business

Business, 22.06.2019 05:00

Xie company identified the following activities, costs, and activity drivers for 2017. the company manufactures two types of go-karts: deluxe and basic. activity expected costs expected activity handling materials $ 625,000 100,000 parts inspecting product 900,000 1,500 batches processing purchase orders 105,000 700 orders paying suppliers 175,000 500 invoices insuring the factory 300,000 40,000 square feet designing packaging 75,000 2 models required: 1. compute a single plantwide overhead rate, assuming that the company assigns overhead based on 125,000 budgeted direct labor hours. 2. in january 2017, the deluxe model required 2,500 direct labor hours and the basic model required 6,000 direct labor hours. assign overhead costs to each model using the single plantwide overhead rate.

Answers: 3

Business, 22.06.2019 06:00

List three careers that require knowledge of science. list three careers that require the use of of math. list three careers that require the use of foreign language. list three careers that require the use of good writing skills. list three careers that require the use of good computer skills.

Answers: 3

Business, 22.06.2019 19:40

Sue now has $125. how much would she have after 8 years if she leaves it invested at 8.5% with annual compounding? a. $205.83b. $216.67c. $228.07d. $240.08e. $252.08

Answers: 1

Business, 22.06.2019 22:30

Luggage world buys briefcases with an invoice date of september 28. the terms of sale are 2/10 eom. what is the net date for this invoice

Answers: 1

You know the right answer?

A company producing custom-made teddy bears is considering several options for expanding their exist...

Questions

English, 02.12.2020 22:40

Mathematics, 02.12.2020 22:40

Geography, 02.12.2020 22:40

Mathematics, 02.12.2020 22:40

English, 02.12.2020 22:40

Mathematics, 02.12.2020 22:40

English, 02.12.2020 22:40

Mathematics, 02.12.2020 22:40

Mathematics, 02.12.2020 22:40

Chemistry, 02.12.2020 22:40

Mathematics, 02.12.2020 22:40

History, 02.12.2020 22:40