Business, 02.02.2021 02:00 damondgriswold12

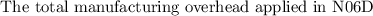

Look Manufacturing Corporation has a traditional costing system in which it applies manufacturing overhead to its products using a predetermined overhead rate based on direct labor-hours (DLHs). The company has two products, N06D and M09K, about which it has provided the following data: N06D M09K Direct materials per unit $ 33.40 $ 61.20 Direct labor per unit $ 6.00 $ 28.00 Direct labor-hours per unit 0.20 1.00 Annual production (units) 48,200 15,000 The company's estimated total manufacturing overhead for the year is $1,754,571 and the company's estimated total direct labor-hours for the year is 24,640. The company is considering using a variation of activity-based costing to determine its unit product costs for external reports. Data for this proposed activity-based costing system appear below: Activities and Activity Measures Estimated Overhead Cost Supporting direct labor (DLHs) $ 862,400 Setting up machines (setups) 476,307 Parts administration (part types) 415,864 Total $ 1,754,571 Expected Activity N06D M09K Total DLHs 9640 15,000 24,640 Setups 1670 1021 2691 Part types 641 267 908 The manufacturing overhead that would be applied to a unit of product N06D under the company's traditional costing system is closest to: (Round your intermediate calculations to 2 decimal places.) Group of answer choices

Answers: 3

Another question on Business

Business, 21.06.2019 20:30

What is the most important type of decision that the financial manager makes?

Answers: 2

Business, 22.06.2019 15:40

Acompany manufactures x units of product a and y units of product b, on two machines, i and ii. it has been determined that the company will realize a profit of $3 on each unit of product a and $4 on each unit of product b. to manufacture a unit of product a requires 7 min on machine i and 5 min on machine ii. to manufacture a unit of product b requires 8 min on mchine i and 5 min on machine ii. there are 175 min available on machine i and 125 min available on machine ii in each work shift. how many units of a product should be produced in each shift to maximize the company's profit p?

Answers: 2

Business, 22.06.2019 21:00

Mr. beautiful, an organization that sells weight training sets, has an ordering cost of $40 for the bb-1 set. (bb-1 stands for body beautiful number 1.) the carrying cost for bb-1 is $5 per set per year. to meet demand, mr. beautiful orders large quantities of bb-1 seven times a year. the stockout cost for bb-1 is estimated to be $50 per set. over the past several years, mr. beautiful has observed the following demand during the lead time for bb-1: demand during lead time probability40 0.150 0.260 0.270 0.280 0.290 0.1total 1.0the reorder point for bb-1 is 60 sets. what level of safety stock should be maintained for bb-1?

Answers: 3

Business, 23.06.2019 05:40

Which two tasks does an industry safety and health engineer perform?

Answers: 1

You know the right answer?

Look Manufacturing Corporation has a traditional costing system in which it applies manufacturing ov...

Questions

Mathematics, 30.09.2020 05:01

Physics, 30.09.2020 05:01

Spanish, 30.09.2020 05:01

Social Studies, 30.09.2020 05:01

Health, 30.09.2020 05:01

Geography, 30.09.2020 05:01

Chemistry, 30.09.2020 05:01

Social Studies, 30.09.2020 05:01

Biology, 30.09.2020 05:01

Physics, 30.09.2020 06:01