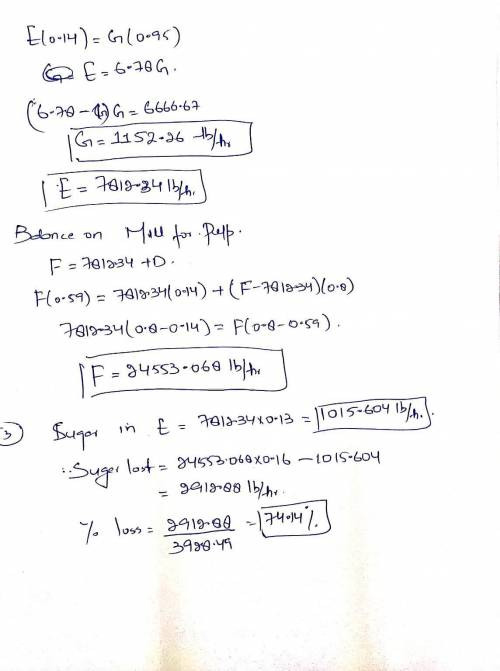

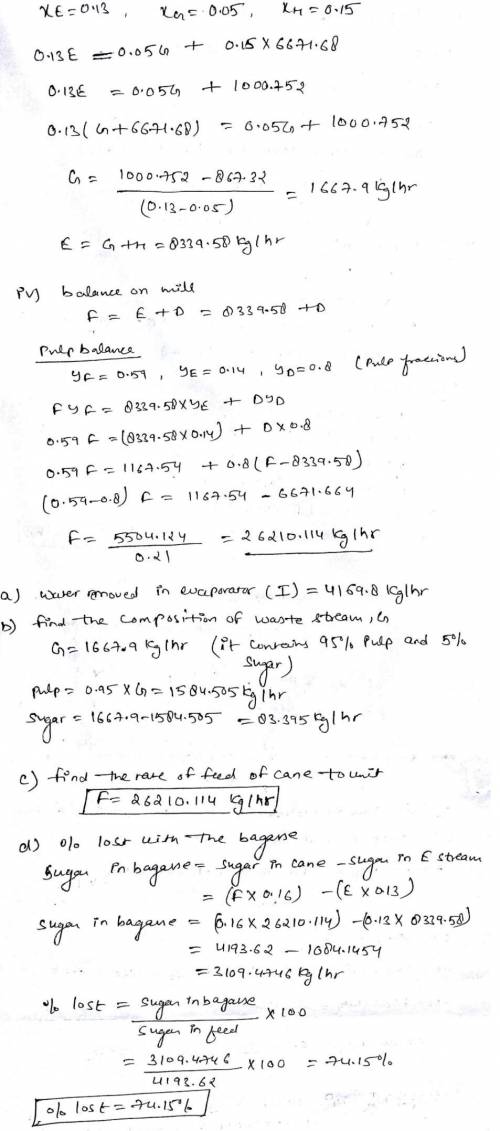

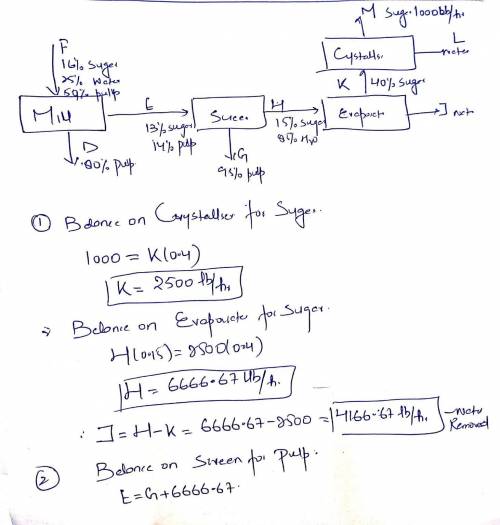

Cane sugar is being manufactured at the rate of 500 kg/hr from sugar canes that have the following composition (% by weight):

Sugar = 16%

Water = 25 %

Pulp = 59 %

The canes are crushed in a mill to mechanically extract the juice and the cellulosic residue (called bagasse) is discarded. The juice containing 13 percent sugar and 14 percent pulp is filtered on vibrating screens to remove the pulp. The resulting clear syrup containing 15 % sugar (rest water) is first concentrated to 40 % in an evaporator and then fed to an evaporator-crystalliser where further water is removed and sugar crystals separate out. Bagasse discarded from the mill contains 80% pulp and solids retained on the screens 95% pulp. Calculate:

a) Mass of canes required per hour

b) Mass of water removed in evaporator per hour

c) Composition (% by weight) of solids retained on screens

d) Percentage of sugar lost in bagasse

Answers: 3

Another question on Chemistry

Chemistry, 22.06.2019 05:50

Why doesn't heat added to water make the tempature rise above 100c

Answers: 2

Chemistry, 22.06.2019 10:30

Earth's axis of rotation is tilted at an angle of 23.5 degrees. what is one change you would see on earth if its axis was not tilted?

Answers: 3

Chemistry, 22.06.2019 11:50

Calculate the molarity of each of the following solutions. part a) 0.12 mol of lino3 in 5.5 l of solution part b) 60.7 g c2h6o in 2.48 l of solution part c) 14.2 mg ki in 100 ml of solution

Answers: 2

Chemistry, 22.06.2019 13:00

Which of the following are good traits of a hypothesis? it will be able to be testedit can predict an outcomeit will explain the observationsall of these

Answers: 2

You know the right answer?

Cane sugar is being manufactured at the rate of 500 kg/hr from sugar canes that have the following c...

Questions

Mathematics, 22.02.2020 04:16

Mathematics, 22.02.2020 04:16

Mathematics, 22.02.2020 04:17

Mathematics, 22.02.2020 04:17