Engineering, 07.03.2020 04:44 holamigosss

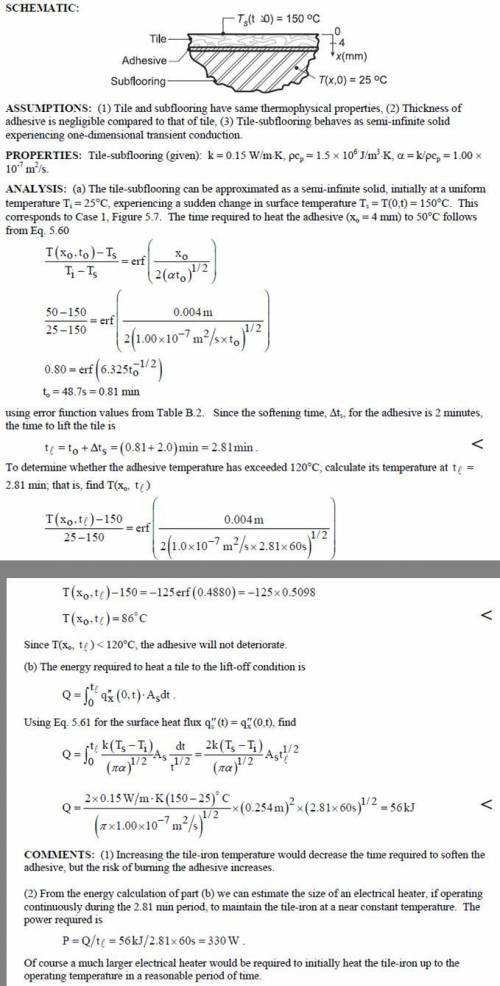

A tile-iron consists of a massive plate maintained at 150 degrees Celsius by an embedded electrical heater. The iron is placed in contact with a tile to soften the adhesive allowing the tile to be easily lifted from the subflooring. The adhesive will soften sufficiently i heated above 50 degrees celsius for at least 2 minutes, but its temperature should not exceed 120 degrees Celsius. Assume the tile and subfloor to have an initial temperature of 25 degrees Celsius and to have equivalent thermophysical properties of k = .15 W/mK and (rho*c_p) = 1.5 * 10 ^ J/m^3K. a) How long will it take a worker using the tile-iron to lift a tile? Will the adhesive temperature exceed 120 degrees C?b) If the tile-iron has a square surface area 254mm to the side, how much energy has been removed from it during the time it has taken to lift the tile?

Answers: 2

Another question on Engineering

Engineering, 04.07.2019 18:20

Air is compressed isentropically from an initial state of 300 k and 101 kpa to a final temperature of 1000 k. determine the final pressure using the following approaches: (a) approximate analysis (using properties at the average temperature) (b) exact analysis

Answers: 1

Engineering, 04.07.2019 19:20

Ashielded metal arc-welding operation is accomplished in a work cell by a fitter and a welder. the fitter takes 5.5 min to load components into the welding fixture at the beginning of the work cycle, and 1.5 min to unload the completed weldment at the end of the cycle. the total ength of the weld seams 1200 mm, and the travel speed used by the welder averages 300 mm/min. every 600 mm of seam length, the welding stick must be changed, which takes 0.8 min. while the fitter is working, the welder is idle (resting): and while the welder is working the fitter is idle. (a) determine the average arc-on time as a fraction of the work cycle time. (b) how much improvement in arc-on time would result if the welder used flux-cored arc welding (manually operated), given that the spool of weld wire must be changed every 10 weldments, and it takes the welder 5.0 min to accomplish the change? (c) what are the production rates for these two cases (weldments completed per hour)? attach your work and solutions.

Answers: 1

Engineering, 06.07.2019 02:30

Around steel bar, made from material with a yield stress of 750mpa, is loaded so that it has stresses co locations of maximum normal stress and maximum shear stress. use maximum shear stress and maximum distortion energy theories to calculate the safety factors for initial yielding failures.

Answers: 3

Engineering, 06.07.2019 03:10

List and describe in sequence the operation process steps for boxf machine?

Answers: 1

You know the right answer?

A tile-iron consists of a massive plate maintained at 150 degrees Celsius by an embedded electrical...

Questions

Mathematics, 09.04.2020 02:06

Computers and Technology, 09.04.2020 02:06

Mathematics, 09.04.2020 02:06

Mathematics, 09.04.2020 02:06

Mathematics, 09.04.2020 02:06

Mathematics, 09.04.2020 02:06