Engineering, 19.03.2020 02:47 plb2007

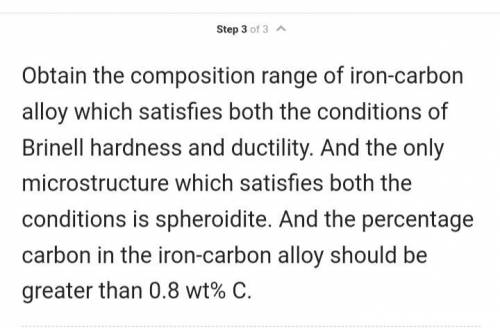

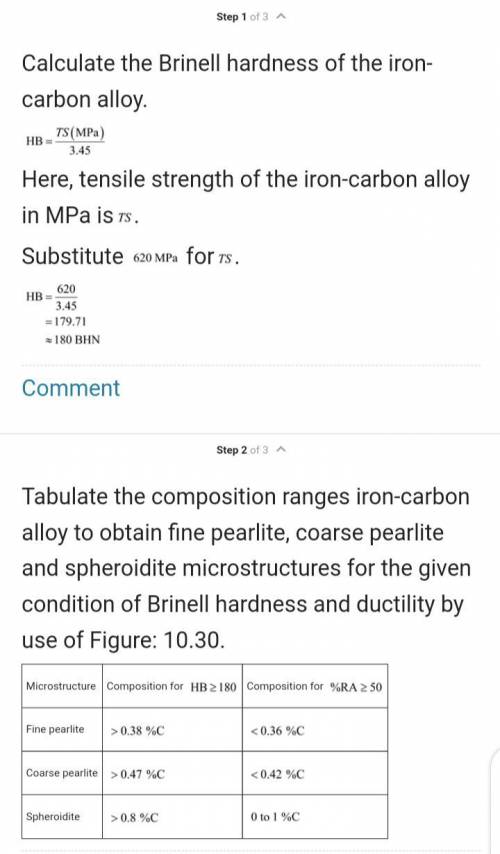

S it possible to produce an iron–carbon alloy that has a minimum tensile strength of 620 MPa (90,000 psi) and a minimum ductility of 50% RA? If so, what will be its composition and microstructure (coarse and fine pearlites and spheroidite are alternatives)? If this is not possible, explain why.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Draw the engineering stress-strain curve for (a) bcc; (b) fcc metals and mark important points.

Answers: 1

Engineering, 04.07.2019 18:20

Athin walled concentric tube exchanger is used to cool engine oil from 160°c to 60°c with water that is available at 25°c acting as a coolant. the oil and water flow rates are each at 2 kg/s, and the diameter of the inner tube is 0.5 m and the corresponding value of the overall heat transfer coefficient is 250 w/m2. oc. how long must the heat exchanger be to accomplish the desired cooling? cpwater=4.187 kj/kg-candcpengine el=2.035 kj/kg·°c, oil . 120]

Answers: 1

Engineering, 04.07.2019 18:20

Prove the equivalence between the two statements of the 2nd law of thermodynamics (i.e., a violation of one statement leads to the violatio the other statement)

Answers: 2

Engineering, 06.07.2019 03:10

Explain the strain-hardening phenomenon on the basis of dislocation - dislocation strain field interactions. also, briefly describe what generally happens to the ductility of a metal that has been strain hardened (i.e. does strain hardening make a metal more ductile or

Answers: 3

You know the right answer?

S it possible to produce an iron–carbon alloy that has a minimum tensile strength of 620 MPa (90,000...

Questions

Computers and Technology, 10.10.2019 02:00

Mathematics, 10.10.2019 02:00

History, 10.10.2019 02:00

Health, 10.10.2019 02:00

Mathematics, 10.10.2019 02:00

History, 10.10.2019 02:00

English, 10.10.2019 02:00

Mathematics, 10.10.2019 02:00

Health, 10.10.2019 02:00

Engineering, 10.10.2019 02:00