Engineering, 24.03.2020 18:01 hellokitty1647

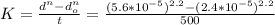

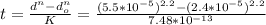

A hypothetical metal alloy has a grain diameter of 2.4 × 10−2 mm. After a heat treatment at 575°C for 500 min, the grain diameter has increased to 5.6 × 10−2 mm. Compute the time required for a specimen of this same material (i. e., d0 = 2.4 × 10−2 mm) to achieve a grain diameter of 5.5 × 10−2 mm while being heated at 575°C. Assume the n grain diameter exponent has a value of 2.2.

Answers: 2

Another question on Engineering

Engineering, 04.07.2019 12:10

On a average work day more than work place firs are reorted

Answers: 1

Engineering, 04.07.2019 18:10

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

Engineering, 04.07.2019 18:10

Apipe with an outside diameter of 15 cm is exposed to an ambient air and surrounding temperature of -20°c. the pipe has an outer surface temperature of 65°c and an emissivity of 0.85. if the rate of heat loss from the pipe surface is 0.95 kw per meter of length, the external convective heat transfer coefficient (h) is: (a) 12.5 w/m"k (b) 18.6 w/mk (c) 23.7 w/mk (d) 27.9 w/mk (e) 33.5 w/mk

Answers: 1

Engineering, 04.07.2019 18:10

Slip occurs via two partial dislocations because of (a) the shorter path of the partial dislocation lines; (b) the lower energy state through partial dislocations; (c) the charge balance.

Answers: 1

You know the right answer?

A hypothetical metal alloy has a grain diameter of 2.4 × 10−2 mm. After a heat treatment at 575°C fo...

Questions

Spanish, 10.12.2021 18:00

Advanced Placement (AP), 10.12.2021 18:00

Biology, 10.12.2021 18:00

Business, 10.12.2021 18:00

Biology, 10.12.2021 18:00

Biology, 10.12.2021 18:00

Mathematics, 10.12.2021 18:00

English, 10.12.2021 18:00

Mathematics, 10.12.2021 18:00

= 7.48 × 10⁻¹³ m/min

= 7.48 × 10⁻¹³ m/min = 477 min

= 477 min