Engineering, 06.05.2020 05:11 7letters22

One way to cool chips mounted on the circuit boards of a computer is to encapsulate the boards in metal frames that provide efficient pathways for conduction to supporting cold plates. Heat generated by the chips is then dissipated by transfer to water flowing through passages drilled in the plates. Because the plates are made from a metal of large thermal conductivity (typically aluminium or copper), they may be assumed to be at a temperature, Ts, cp.

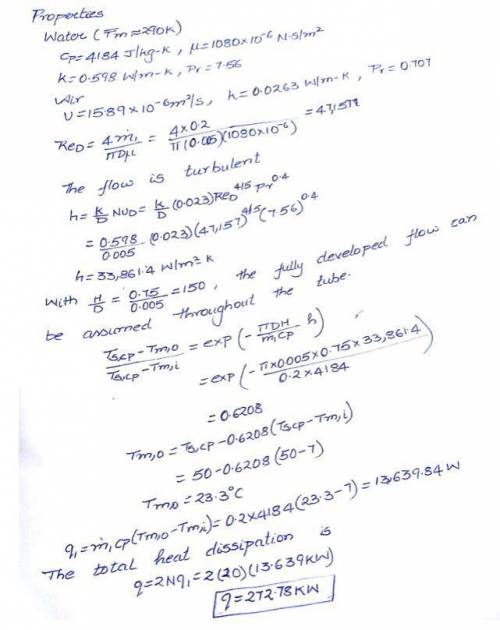

Consider circuit boards attached to cold plates of height H = 750 mm and width L = 600 mm, each with N 10 passages of diameter D = 5 mm. If operating conditions maintain plate temperatures of Ts, cp-50°C with water flow at m =0.2 kg/s per passage and Tmi =70C, how much heat may be dissipated by the circuit boards? Evaluate the properties of water at 290 K.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Water in a partially filled large tank is to be supplied to the roof top, which is 8 m above the water level in the tank, through a 2.2-cm-internal-diameter pipe by maintaining a constant air pressure of 300 kpa (gage) in the tank. if the head loss in the piping is 2 m of water, determine the discharge rate of the supply of water to the roof top in liters per second.

Answers: 3

Engineering, 04.07.2019 18:10

Ahot wire operates at a temperature of 200°c while the air temperature is 20°c. the hot wire element is a tungsten wire of 5 um diameter and 2 mm in length. plot using excel current, heat transfer and heat generated by the wire for air velocity varying from 1-10 m/s in steps of lm/s? matlab the sensor voltage output, resistance, or assume nu 0.989 re033pr13 take air properties at tr (200°c20°c)/2 = 110°c properties of tungsten: c 0.13 kj/kg.k 3 p 19250 kg/m k (thermal conductivity) = 174 w/m.k

Answers: 2

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

Engineering, 04.07.2019 19:10

A)-in the process of engineering design, explain the contribution of material selection. b)- explain the procedure of synthesis as is employed in engineering design. c)- is there any relationship between ergonomics and engineering design? explain. d)- safety consideration in engineering design includes human, product and the enviroment . explain how safety will be incorporated into the design?

Answers: 3

You know the right answer?

One way to cool chips mounted on the circuit boards of a computer is to encapsulate the boards in me...

Questions

Mathematics, 21.06.2020 00:57

Mathematics, 21.06.2020 00:57

Mathematics, 21.06.2020 00:57

Mathematics, 21.06.2020 00:57

Advanced Placement (AP), 21.06.2020 00:57

Geography, 21.06.2020 00:57

Mathematics, 21.06.2020 00:57

Computers and Technology, 21.06.2020 00:57

Mathematics, 21.06.2020 00:57

Mathematics, 21.06.2020 00:57