Engineering, 05.05.2020 01:49 reyrey216

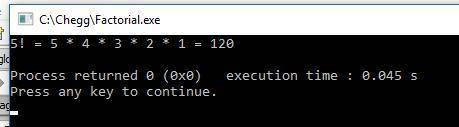

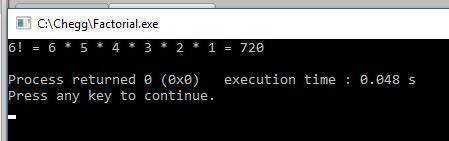

#include using namespace std; void PrintFactorial(int factCounter, int factValue){ int nextCounter; int nextValue; if (factCounter == 0) { // Base case: 0! = 1 cout << "1" << endl; } else if (factCounter == 1) { // Base case: Print 1 and result cout << factCounter << " = " << factValue << endl; } else { // Recursive case cout << factCounter << " * "; nextCounter = factCounter - 1; nextValue = nextCounter * factValue; /* Your solution goes here */ } } int main() { int userVal; cin >> userVal; cout << userVal << "! = "; PrintFactorial(userVal, userVal); return 0; }

Answers: 1

Another question on Engineering

Engineering, 04.07.2019 18:10

Steel is coated with a thin layer of ceramic to protect against corrosion. what do you expect to happen to the coating when the temperature of the steel is increased significantly? explain.

Answers: 1

Engineering, 04.07.2019 19:20

At steady state, air at 200 kpa, 325 k, and mass flow rate of 0.5 kg/s enters an insulated duct having differing inlet and exit cross-sectional areas. the inlet cross-sectional area is 6 cm2. at the duct exit, the pressure of the air is 100 kpa and the velocity is 250 m/s. neglecting potential energy effects and modeling air as an 1.008 kj/kg k, determine ideal gas with constant cp = (a) the velocity of the air at the inlet, in m/s. (b) the temperature of the air at the exit, in k. (c) the exit cross-sectional area, in cm2

Answers: 2

Engineering, 04.07.2019 19:20

Ashielded metal arc-welding operation is accomplished in a work cell by a fitter and a welder. the fitter takes 5.5 min to load components into the welding fixture at the beginning of the work cycle, and 1.5 min to unload the completed weldment at the end of the cycle. the total ength of the weld seams 1200 mm, and the travel speed used by the welder averages 300 mm/min. every 600 mm of seam length, the welding stick must be changed, which takes 0.8 min. while the fitter is working, the welder is idle (resting): and while the welder is working the fitter is idle. (a) determine the average arc-on time as a fraction of the work cycle time. (b) how much improvement in arc-on time would result if the welder used flux-cored arc welding (manually operated), given that the spool of weld wire must be changed every 10 weldments, and it takes the welder 5.0 min to accomplish the change? (c) what are the production rates for these two cases (weldments completed per hour)? attach your work and solutions.

Answers: 1

Engineering, 06.07.2019 02:30

Air (c-1.006 kj/kg.k, r-0.287 kj/kg.k) enters a nozzle steadily at 280 kpa and 77°c with a velocity of 50 m/s and exits at 85 kpa and 320 m/s. the heat losses from the nozzle to the surrounding medium at 20°c are estimated to be 3.2 kj/kg. determine (a) the exit temperature and (b) the total entropy change for this process. solve this problem using constant specific heats.

Answers: 1

You know the right answer?

#include using namespace std; void PrintFactorial(int factCounter, int factValue){ int nextCounter;...

Questions

Arts, 17.11.2020 18:50

Mathematics, 17.11.2020 18:50

History, 17.11.2020 18:50

Social Studies, 17.11.2020 18:50

Mathematics, 17.11.2020 18:50

Mathematics, 17.11.2020 18:50

Advanced Placement (AP), 17.11.2020 18:50

Mathematics, 17.11.2020 18:50