Engineering, 03.11.2020 17:20 logangiggles02

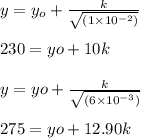

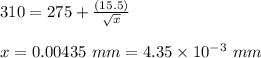

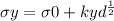

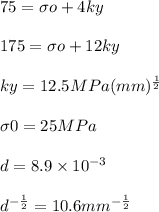

(a) The lower yield point for an iron that has an average grain diameter of 1 x 10-2 mm is 230 MPa. At a grain diameter of 6 x 10-3 mm, the yield point increases to 275 MPa. At what grain diameter will the lower yield point be 310 MPa? (b) Predict the yield strength of the iron when the average grain diameter is 8.0 x 10-3 mm.

Answers: 1

Another question on Engineering

Engineering, 03.07.2019 14:10

Explain the difference laminar and turbulent flow. explain it with the shear stress and the velocity profiles.

Answers: 1

Engineering, 04.07.2019 12:10

On a average work day more than work place firs are reorted

Answers: 1

Engineering, 04.07.2019 18:10

Coiled springs ought to be very strong and stiff. si3n4 is a strong, stiff material. would you select this material for a spring? explain.

Answers: 2

Engineering, 04.07.2019 18:10

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

You know the right answer?

(a) The lower yield point for an iron that has an average grain diameter of 1 x 10-2 mm is 230 MPa....

Questions

Mathematics, 15.02.2021 01:00

Health, 15.02.2021 01:00

Mathematics, 15.02.2021 01:00

Physics, 15.02.2021 01:00

Mathematics, 15.02.2021 01:00

Mathematics, 15.02.2021 01:00

Mathematics, 15.02.2021 01:00

Mathematics, 15.02.2021 01:00

English, 15.02.2021 01:00

Mathematics, 15.02.2021 01:00

Mathematics, 15.02.2021 01:00

and 157.5 MPa".

and 157.5 MPa".

.

.

value that is= 157.5 MPa

value that is= 157.5 MPa