Engineering, 15.02.2021 20:30 laywah4

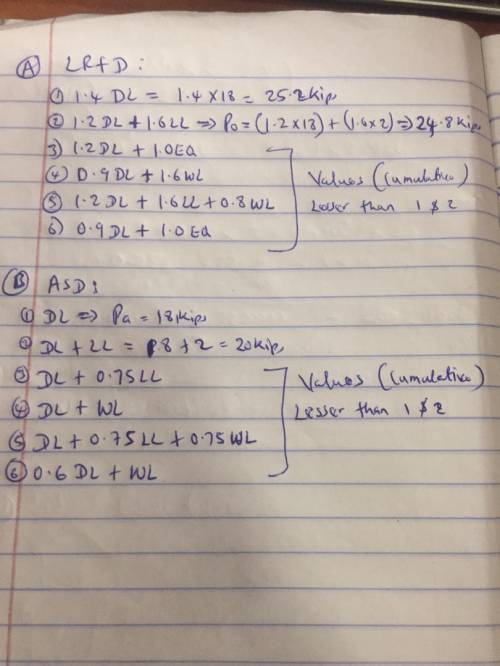

A tension member must be designed for a service dead load of 18 kips and a service live load of 2 kips.

Required:

a. If load and resistance factor design is used, determine the maximum factored load (required strength) and the controlling AISC load combination.

b. If allowable strength design is used, determine the maximum load (required strength) and the controlling AISC load combination.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Determine whether or not it is possible to compress air adiabatically from k to 140 kpa and 400 k. what is the entropy change during this process?

Answers: 3

Engineering, 04.07.2019 18:10

You are making beer. the first step is filling the glass carboy with the liquid wort. the internal diameter of the carboy is 15 in., and you wish to fill it up to a depth of 2 ft. if your wort is drawn from the kettle using a siphon process that flows at 3 gpm, how long will it take to fill?

Answers: 1

Engineering, 04.07.2019 18:10

Compute the pressure drop of 30°c air flowing with a mean velocity of 8 m/s in a circular sheet-metal duct 300 mm in diameter and 15 m long. use a friction factor, f 0.02, and pair = 1.1644 kg/m a. 37.26 pa b. 25.27 pa n c. 29.34 pa d. 30.52 pa

Answers: 1

Engineering, 04.07.2019 19:10

What is a monomer? how do they form a ploymer from the view point of chemical bonding?

Answers: 1

You know the right answer?

A tension member must be designed for a service dead load of 18 kips and a service live load of 2 ki...

Questions

Advanced Placement (AP), 18.12.2020 17:10

Mathematics, 18.12.2020 17:10

Spanish, 18.12.2020 17:10

Mathematics, 18.12.2020 17:10

Mathematics, 18.12.2020 17:10

Advanced Placement (AP), 18.12.2020 17:10