Engineering, 15.05.2021 01:10 orozcoalbeert

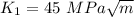

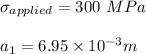

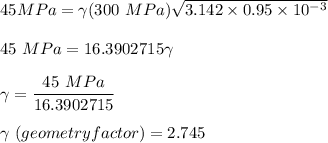

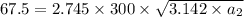

A structural component is fabricated from an alloy that has a plane strain fracture toughness of 45 MPam. It has been determined that this component fails at a stress of 300 MPa when the maximum length of a surface crack is 0.95 mm. What is the maximum allowable surface crack length (in mm) without fracture for this same component exposed to a stress of 300 MPa and made from another alloy with a plane strain fracture toughness of 67.5 MPam

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Different types of steels contain different elements that alter the characteristics of the steel. for each of the following elements, explain what the element does when alloyed with steel.

Answers: 2

Engineering, 04.07.2019 18:10

Shafts are machine elements that are used to a) carry axial loads b) direct shear loads c) transmit power d) rotate at constant speed e) none of the above circular and square shafts subjected to the same torque under the same circum behave a) the same way b) almost the same way

Answers: 2

Engineering, 04.07.2019 18:10

Manometers are good examples of measuring instruments, nowadays they are not as common as before. a)-capacitive probe gauges b)-gravitational gauges deformation ) gauges d)-digital gauges

Answers: 1

Engineering, 04.07.2019 19:10

Asteel wire of 2 mm diameter is fixed between two points located 2 m apart. the tensile force in the wire is 250n, if its density of steel is given by 7830 kg/m3 the fundamental frequency of vibration hz? ?

Answers: 3

You know the right answer?

A structural component is fabricated from an alloy that has a plane strain fracture toughness of 45...

Questions

Geography, 25.07.2019 18:30

Spanish, 25.07.2019 18:30

Mathematics, 25.07.2019 18:30

Geography, 25.07.2019 18:30

History, 25.07.2019 18:30

Mathematics, 25.07.2019 18:30

geometry factor

geometry factor