Mathematics, 13.10.2020 06:01 iPlayOften3722

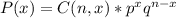

This exercise illustrates that poor quality can affect schedules and costs. A manufacturing process has 70 customer orders to fill. Each order requires one component part that is purchased from a supplier. However, typically, 3% of the components are identified as defective, and the components can be assumed to be independent.

Required:

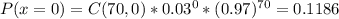

a. If the manufacturer stocks 70 components, what is the probability that the 70 orders can be filled without reordering components?

b. If the manufacturer stocks 102 components, what is the probability that the 100 orders can be filled without reordering components?

c. If the manufacturer stocks 105 components, what is the probability that the 100 orders can be filled without reordering components?

Answers: 3

Another question on Mathematics

Mathematics, 21.06.2019 17:00

(! ) three cylinders have a height of 8 cm. cylinder 1 has a radius of 1 cm. cylinder 2 has a radius of 2 cm. cylinder 3 has a radius of 3 cm. find the volume of each cylinder

Answers: 1

Mathematics, 21.06.2019 20:30

Your friend uses c=50p to find the total cost, c, for the people, p, entering a local amusement park what is the unit rate and what does it represent in the context of the situation?

Answers: 2

You know the right answer?

This exercise illustrates that poor quality can affect schedules and costs. A manufacturing process...

Questions

Mathematics, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10

Chemistry, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10

Chemistry, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10

English, 11.02.2021 14:10

Health, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10

Mathematics, 11.02.2021 14:10