We wish to produce a 0.1-in. thick plate of 3105 aluminum having a tensile strength of at least 25,000 psi and a % elongation of at least 5%. the original thickness of the plate is 3 in. the maximum cold work in each step is 80%. describe the cold working and annealing steps required to make this product. compare this process with what you would recommend if you could do the initial deformation by hot working.

Answers: 1

Another question on Physics

Physics, 22.06.2019 01:30

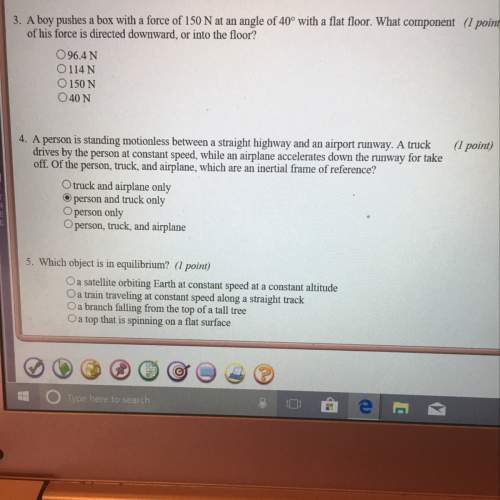

Astone is dropped with no initial velocity from the top of a cliff and hits the ground a time of 3.9 s later. what is the height of the cliff, in units of meters? you may assume that air resistance is negligible. give the answer as a positive number question 15 a figure skater is rotating at a rate of 200 revolutions per minute. what is the angular speed, in units of rad/s? 200 o 20.9 12000 o 3.33

Answers: 2

Physics, 22.06.2019 04:20

Awave is produced in a rope. the wave has a speed of 33 m/s and a frequency of 22 hz.

Answers: 3

Physics, 22.06.2019 14:30

Which of these is constant for all types of electromagnetic radiation in a vacuum? select one: a. wavelength b. frequency c. photon energy d. amplitude e. velocity

Answers: 3

You know the right answer?

We wish to produce a 0.1-in. thick plate of 3105 aluminum having a tensile strength of at least 25,0...

Questions

Physics, 03.06.2021 02:20

Mathematics, 03.06.2021 02:20

Physics, 03.06.2021 02:20

Mathematics, 03.06.2021 02:20

Mathematics, 03.06.2021 02:20

Arts, 03.06.2021 02:20

Mathematics, 03.06.2021 02:20

Chemistry, 03.06.2021 02:20