Business, 06.05.2020 04:24 mattgraham366

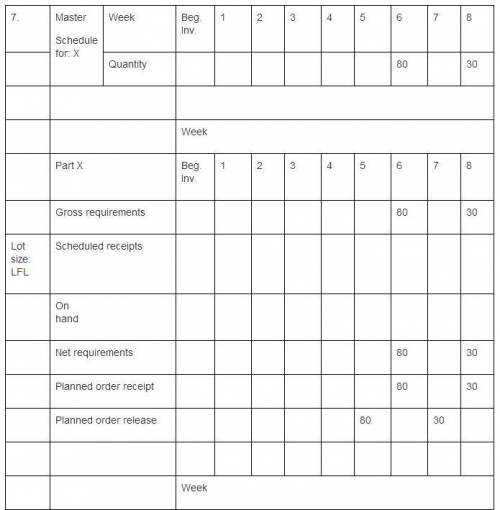

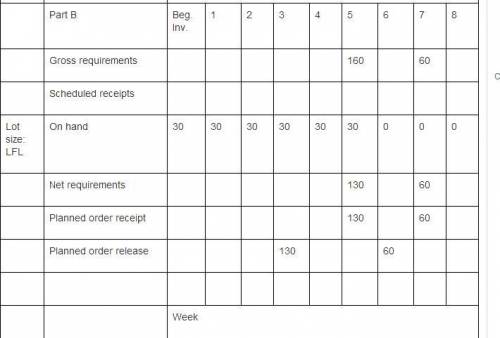

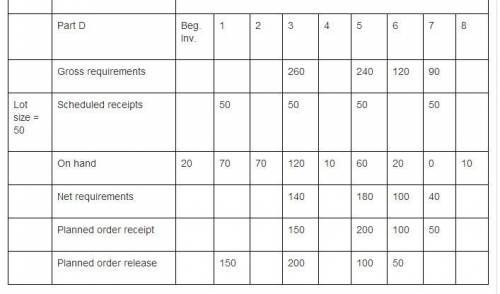

Eighty units of end item X are needed at the beginning of week 6, and another 30 units are needed at the beginning of week 8. Prepare a material requirements plan for component D. D can only be ordered in whole cases (50 units per case). One case of D is automatically received every other week, beginning in week 1 (i. e., weeks 1, 3, 5, 7). Also, there are 30 units of B and 20 units of D now on hand. Lead times for all items are a function of quantity: one week for up to 100 units, two weeks for 101 to 200 units, three weeks for 201 to 300 units, and four weeks for 301 or more units. (Leave no cells blank - be certain to enter "0" wherever required.)

Answers: 2

Another question on Business

Business, 21.06.2019 20:50

Suppose the price of frozen yogurt, a substitute for ice cream, increases. what happens to equilibrium price and quantity of ice cream? a. the price and quantity of ice cream both increase b. the price and quantity of ice cream both decrease c. the price of ice cream increases and the quantity decreases d. the price of ice cream decreases and the quantity increases

Answers: 3

Business, 21.06.2019 21:30

The following information relates to wagner, inc.: advertising costs $ 18 comma 600 administrative salaries 17 comma 800 delivery vehicle depreciation 1 comma 500 factory repair and maintenance 600 indirect labor 10 comma 000 indirect materials 18 comma 000 manufacturing equipment depreciation 3 comma 000 office rent 58 comma 000 president's salary 1 comma 100 sales revenue 600 comma 000 sales salary 5 comma 200 how much were wagner's period costs

Answers: 3

Business, 22.06.2019 03:40

Electronics assembly inc. is a contract manufacturer that assembles consumer electronics for a number of companies. currently, the operations manager is assessing the capacity requirements as input into a bid for a job to assemble cell phones for a major global company. the company would assemble three models of cell phones in the same assembly cell. setup time between the phones is negligible. electronics assembly inc. operates two 8-hour shifts for 275 days per year. cell phone demand forecast (phones/year) processing time (minutes/phone) mars 47,000 19.8 saturn 35,000 20.7 neptune 7,500 16.2 a. calculate total capacity required by line. b. determine the total operating time available. c. calculate the total number of assembly cells. (round up your answer to the next whole number.)

Answers: 2

Business, 22.06.2019 08:40

Gerda, a real estate agent, is selling a moderately priced house in a subdivision. she knows from her uncle that the factory being built half a mile from the subdivision will be manufacturing dog food, using a process that creates a very strong odor that permeates the surrounding neighborhood. a buyer, who is unaware of the type of factory under construction, makes an offer on one of the houses gerda is selling, and within a short time, the deal goes through. what does this scenario best illustrate?

Answers: 3

You know the right answer?

Eighty units of end item X are needed at the beginning of week 6, and another 30 units are needed at...

Questions

Mathematics, 17.04.2021 19:30

Arts, 17.04.2021 19:40

Mathematics, 17.04.2021 19:40

History, 17.04.2021 19:40

Engineering, 17.04.2021 19:40