Engineering, 14.12.2019 05:31 kingdrex4772

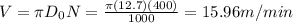

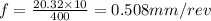

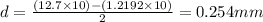

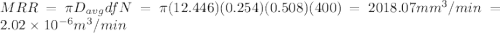

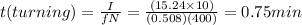

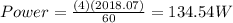

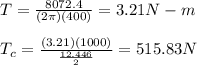

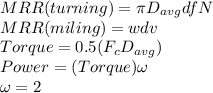

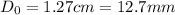

A15.24 cm long, 1.27 cm diameter 304 stainless steel rod is being reduced in diameter to 1.2192 cm by turning on a lathe. the spindle rotates at n=400 rpm, and the tool is travelling at an axial speed of 20.32 cm/min. calculate the cutting speed, material removal rate, power dissipated, and cutting force.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Abrake has a normal braking torque of 2.8 kip in and heat-dissipating cast-iron surfaces whose mass is 40 lbm. suppose a load is brought to rest in 8.0 s from an initial angular speed of 1600 rev/min using the normal braking torque; estimate the temperature rise of the heat dissipating surfaces.

Answers: 3

Engineering, 04.07.2019 18:10

Coiled springs ought to be very strong and stiff. si3n4 is a strong, stiff material. would you select this material for a spring? explain.

Answers: 2

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

Engineering, 04.07.2019 18:20

Derive the correction factor formula for conical nozzle i=-(1+ cosa) and calculate the nozzle angle correction factor for a nozzle whose divergence hal-fangle is 13 (hint: assume that all the mass flow originates at the apex of the cone.

Answers: 3

You know the right answer?

A15.24 cm long, 1.27 cm diameter 304 stainless steel rod is being reduced in diameter to 1.2192 cm b...

Questions

Physics, 23.06.2019 00:30

History, 23.06.2019 00:30

Biology, 23.06.2019 00:30

Geography, 23.06.2019 00:30

History, 23.06.2019 00:30

Mathematics, 23.06.2019 00:30

;

;  ;

;